Not sure how composites can help? Take a look at some case studies how we assisted our clients before. Or give us a call

-

Express Product Development

When we were approached to produce a part and deliver the first sample within a 2 week timeline, we agreed instantly because we always deliver on time and to specification. We signed the PO and made the mold design within the day. Utilizing our partner CNC shop and utilizing aluminum patterns to cut faster, we were able to build the first mold by the end of the first week, and the first sample 2 days afterwards. Shipping the first pre-production part to the client 3 days before it was due. They were so satisfied they ordered the remaining order before the 2 weeks were done!

-

Acoustic Sound Deadening

We had a client reach out to us with a very specific problem, and a not so clear understanding. They needed to make something very light, but also not hollow to induce sound. But to dampen it. We presented Nomex as a solution to fill their design and reduce the noise because of the material and shape properties it has. They were very intrigued and we built with their engineers prototypes that were tested with their very critical clients. The results? A resounding success! So much so they had other products they needed produced. The path was set, design and build the next generation product with the knowledge gained and CACF would build it all.

-

Rapid Prototyping Drone Legs

When we received the files for these legs it was a straight forward project. So we proceeded through our process; Design the molds, machined them and built to specifications. All within the required timeline. Upon delivery and testing the client realized their design did not meet the requirements they had desired. They were unsure how they could get the Carbon Fiber to work best for them. CACF was then tasked to develop a solution to their problem based on our Carbon expertise. We modified the design through a variety of solutions, tested and tested some more, then succeed that requirement. Show casing to the client each step of the way. Finally we rebuilt the molds and delivering the entire production order.

-

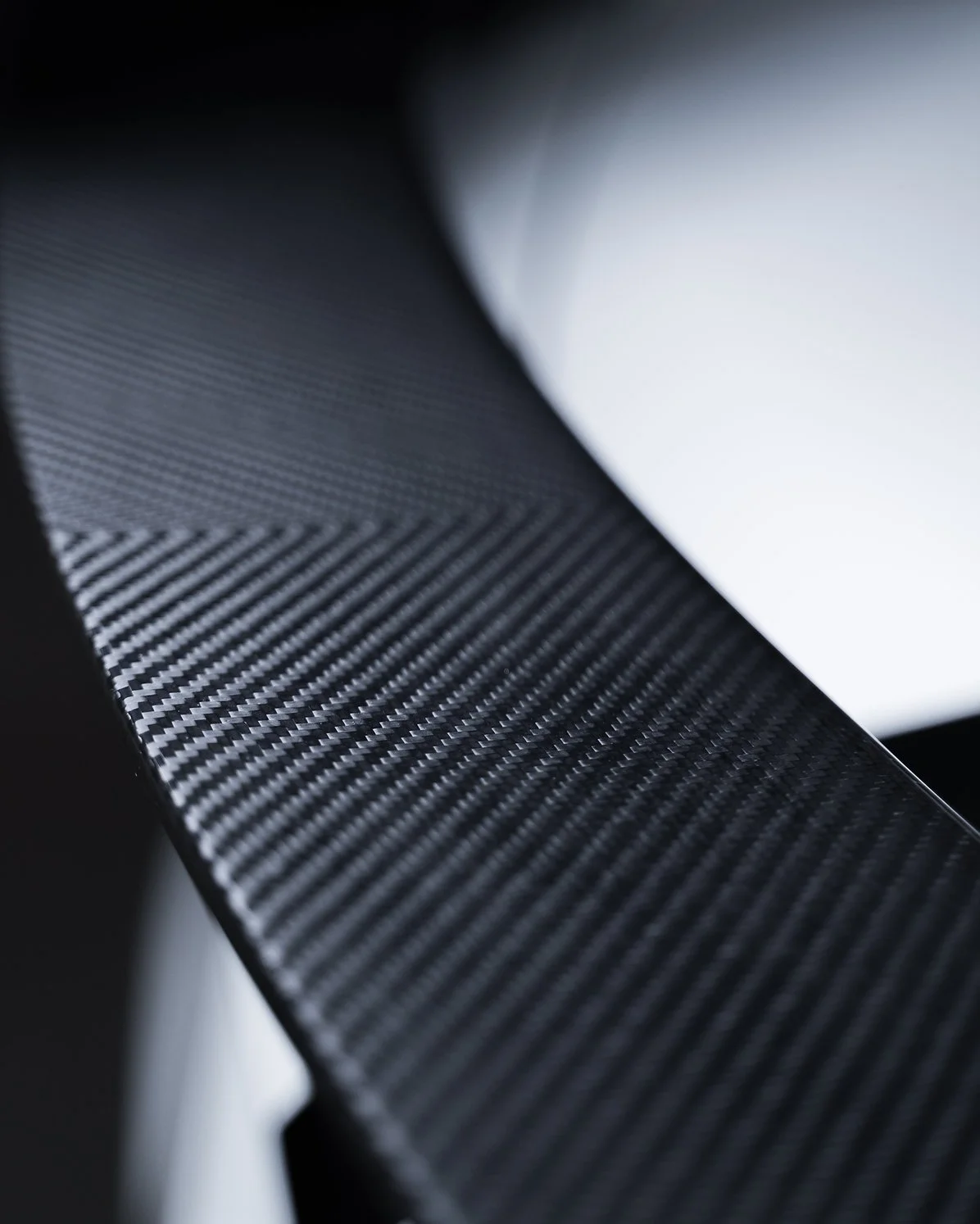

For The Show-Offs

When quality is of the up most importance CACF delivers. The client had to outsource the production of their critical Liquid Carbon Fiber parts to CACF because their team was unable to accurately produce it in-house. The double curvature and complex geometry meant there was no room for error. CACF developed techniques that produced the quality necessary and had the lowest reject rate for such a part. It has now become our specialty. We even produced our own Corvette high wing spoiler with the same techniques.

-

Light Weighting Robotic Jigs

A North America OEM had a problem. Its new assembly line had difficulties with their robots because the weight of the new front fascia was wearing down the motors. They needed less strain and therefore a lighter load. The only area to reduce weight? Their assembly arm jigs. Their plate was already made of aluminum. Carbon Fiber couldn’t be possible? Could it? They reached out to CACF to learn more about what Carbon Fiber could do. How much lighter the plate could be made and could it be delivered on time for a test study? We worked with their engineers and provided the numbers they needed to make a decision. They pulled the trigger and CACF got to work right away. Designing the layup and optimizing the part. In the end? 30% weight reduction and a stiffer plate than the aluminum. They ordered more!

-

When a Product Needs To Flex

Not all carbon has to be rigid. Sometimes there are designs that can use the properties of Carbon Fiber to flex in precise manners to create a tight fit. This was the case of this bicycle bottle cage. The client did not know what level of thickness the part needed to be. It had to carry 750ml worth of liquid weight over bumpy terrain but also weight under 25grams. By utilizing our knowledge of fiber ply placement and experimenting with multiple prototypes we produced a design that functions just as it was intended. And weights at a mere 22 grams!

-

When Woven Is Not An Option

We produce 90% of all our parts from woven carbon fibers. It provides the best tensile strength to weight ratio. However some people like the look of a chopped Carbon Fiber look. Very similar to Lamborghini and often referred to as Forged Carbon Fiber. This is anything but forged. Simply an aesthetically pleasing exterior cover over structural woven layers. We were more than happy to build designs that utilized this material and we like the results!