Our Services

Quality Control

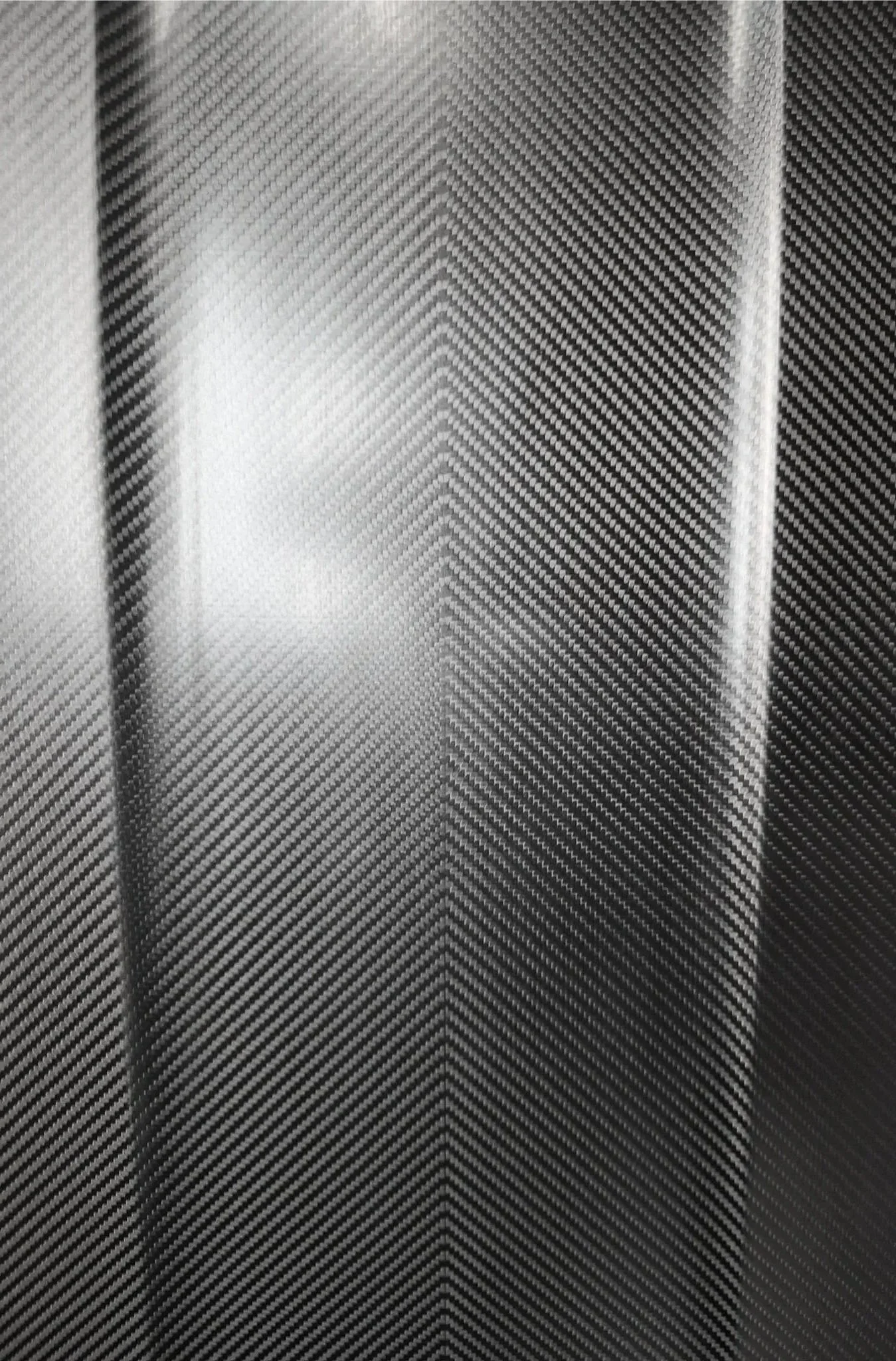

At our facility, quality control is an integral part of every stage in carbon fiber manufacturing. We focus on three critical factors—temperature, compaction, and fit & finish—to ensure every component meets stringent performance and aesthetic standards.

Temperature Control: We meticulously monitor all thermal processes, from prepreg storage to autoclave curing. Maintaining precise temperature profiles is essential to achieve complete resin polymerization, optimal fiber-to-resin bonding, and consistent laminate properties. Real-time sensors and automated monitoring systems allow us to control heating and cooling rates, preventing thermal distortion and ensuring dimensional stability across the part.

Compaction: Proper compaction of the laminate is critical to eliminate voids, achieve uniform fiber volume fraction, and maximize structural performance. We use a combination of vacuum bagging, debulking cycles, and controlled autoclave pressure to consolidate each ply accurately. This ensures the part reaches the designed strength, stiffness, and fatigue resistance while maintaining uniform thickness and surface quality.

Fit & Finish: Surface aesthetics and dimensional accuracy are essential, particularly for high-performance and visible components. Every part is inspected for smoothness, edge integrity, and conformity to engineering tolerances. Advanced measurement tools and visual inspections verify that the part meets both functional and cosmetic requirements. Minor corrections are performed only under strict quality protocols to maintain structural integrity.

-

We specialize in high-volume carbon fiber and composite production, delivering consistent, precision-engineered parts at scale for motorsport, automotive, marine, and sporting applications. Our advanced manufacturing capabilities combine hand layup, CNC-cut prepreg kits, and state-of-the-art autoclave curing to ensure repeatable quality across large production runs.

Our team leverages optimized production workflows and rigorous process controls to maintain uniform fiber orientation, laminate thickness, and mechanical performance in every component. By integrating digital design, kit cutting, and part curing automation, we minimize material waste, reduce cycle times, and maximize throughput without compromising structural integrity or surface finish.

We also implement comprehensive quality assurance protocols, including in-line inspections, and dimensional verification ensuring that each part meets or exceeds customer specifications. Our 20,000 sq ft facility can handle high-volume production and can scale according to costs and volumes of each order. We are efficient, and capable of handling complex geometries and multi-part assemblies, making CACF ideal for both production of prototypes and full-scale manufacturing.

-

Our specialty is the production of advanced composite components using prepreg carbon fiber, delivering the highest levels of precision, performance, and reliability. Our process leverages aerospace-grade materials and autoclave technology to produce parts that are exceptionally lightweight, strong, and dimensionally stable. From concept to completion, we maintain tight control over every variable to ensure consistency, repeatability, and structural integrity across all parts we manufacture.

Prepreg carbon fiber offers unmatched fiber-to-resin control, as each ply is pre-impregnated with a carefully measured resin matrix. This eliminates the inconsistencies found in traditional wet layup processes and enables the production of laminates with precise mechanical properties, minimal voids, and superior surface finish. Our engineering team designs optimized layup schedules and fiber orientations to achieve peak strength-to-weight ratios and tailored stiffness in critical load-bearing applications.

During fabrication, we apply exacting layup and de-bulking procedures followed by autoclave curing to ensure complete consolidation and void-free bonding. The result is a component that meets or exceeds the highest industry standards for structural performance, thermal stability, and aesthetic quality.

Prepreg carbon fiber is ideal for aerospace, automotive, marine, robotics, and performance sporting applications where weight savings and strength are paramount. By combining advanced materials with our precision manufacturing expertise, we deliver components that embody innovation, reliability, and technical excellence—engineered to perform under the most demanding conditions.

-

We can also produce high-quality composite components made from prepreg fiberglass, delivering exceptional precision, consistency, and structural integrity. Using the same advanced processes we apply to carbon fiber manufacturing, our fiberglass production emphasizes dimensional accuracy, strength-to-weight optimization, and cost-effective performance for demanding industrial, marine, and transportation applications.

Our engineering team carefully designs layup schedules to meet specific thermal and structural requirements, allowing us to produce components with high fatigue resistance and excellent surface quality. Prepreg fiberglass also offers outstanding electrical insulation, corrosion resistance, and vibration damping, making it ideal for enclosures, panels, fairings, and structural housings.

By combining advanced composite manufacturing techniques with the versatility of fiberglass, we provide clients with lightweight, durable, and affordable alternatives to metal or carbon fiber components. Our commitment to precision, repeatability, and quality assurance ensures that every fiberglass part we produce performs reliably and looks exceptional, project after project.

-

We provide comprehensive CAD-based surface modeling and mold design services that form the foundation of precision composite manufacturing. Our team leverages advanced CAD software (Rhino 3D and Fusion 360) to transform complex product concepts into highly accurate digital models, ensuring every contour, radius, and feature is optimized for performance, manufacturability, and aesthetics.

Our mold design services translate these models into practical, high-performance tooling solutions. We engineer molds for both carbon fiber and fiberglass components, incorporating considerations for draft angles, thermal expansion, and release characteristics.

By combining state-of-the-art digital tools with engineering expertise, our surface modeling and mold design services deliver precision, performance, and manufacturability, enabling flawless composite parts from prototype to production.

-

We provide precision CNC cutting services that form the foundation for high-performance composite manufacturing. Our in-house 3-axis CNC machining capabilities allow us to create accurate and repeatable molds. Our 3-Axis CNC is ideal for molds with simpler geometries, planar surfaces, and consistent contours. It can fit parts 8ft X 4ft X 4in By leveraging advanced CAD/CAM integration, we ensure that every tool path is optimized for accuracy, efficiency, and surface quality.

For more complex or intricate geometries we utilize our network of trusted partners for 5-axis CNC mold cutting. This approach allows us to produce molds with deep undercuts, compound angles, and highly contoured surfaces that cannot be achieved with standard 3-axis equipment. Our CNC partner can handle parts as large as cars in their machine!

All molds, whether 3-axis in-house or 5-axis outsourced, undergo thorough inspection and verification, including dimensional checks and surface finish assessment.

By combining flexible in-house capabilities with strategic 5-axis outsourcing, we deliver CNC molds that are accurate, durable, and ready for high-quality composite production, supporting both prototyping and full-scale manufacturing projects.

-

Kit cutting is a critical step in composite manufacturing, as the accuracy of each ply directly impacts the final component’s structural performance, dimensional integrity, and surface quality.

Our carbon fiber kit cutting service leverages Gerber cutting technology to ensure precise, repeatable, and efficient preparation of pre-preg plies for layup. We also use Fusion 360 CAM for nesting our patterns into the machine.

Using our Gerber Paragon Cutter , we can accurately cut carbon fiber plies according to digital templates. Each ply is cut with exact fiber orientation, edge definition, and ply geometry, reducing material waste and minimizing variability between parts.

Our skilled technicians oversee the cutting process, verifying material quality, checking nesting efficiency, and ensuring that each kit is complete and organized according to its layup schedule. They maintain tight control over environmental conditions, including humidity and temperature, to protect the integrity of the prepreg material. Each completed kit is labeled, sequenced, and packaged to facilitate smooth, error-free transitions into subsequent layup stages.

-

Our hand layup services for carbon fiber components showcases the exceptional skill, precision, and technical expertise of our team. Hand layup remains a critical process in composite manufacturing, particularly for complex geometries, low-volume production, and high-performance parts where precision and craftsmanship are essential. Our highly trained technicians meticulously place each prepreg ply according to engineered layup schedules, ensuring perfect fiber orientation, alignment, and ply sequencing. This attention to detail is essential for achieving optimal structural performance, stiffness, and weight efficiency. Our technicians are adept at handling intricate contours, tight radii, and variable surface transitions, maintaining fiber integrity and preventing bridging, wrinkles, or misalignment.

By combining advanced materials with human skill and judgment, our hand layup service delivers carbon fiber components with exceptional surface quality, dimensional accuracy, and structural reliability. Whether for prototypes, custom parts, or production components, our team’s craftsmanship ensures that every piece reflects the highest standards of engineering excellence and precision manufacturing.

-

With prepreg to control both resin and fibers and a vacuum bag to remove air, it takes one last step to produce laminates of the highest quality. Our composite manufacturing equipment includes an oven inside a high-pressure vessel, autoclaves apply up to 20 times atmospheric pressure during the cure cycle. This extreme environment provides the highest quality laminates, squeezing fiber bundles tightly and leaving exactly enough resin without voids. That’s still not enough, so our systems control and log the cure, so we can guarantee a perfect part every time and maintain an audit trail.

We currently run 2 autoclaves with the following specifications:

6ft X 15Ft internal dimensions

Computerized monitoring and control.

-

We provide expert low-volume and one-off carbon fiber production services, delivering precision-engineered, high-performance components tailored to your exact specifications. Ideal for prototyping, custom projects, and specialized applications, our approach combines advanced materials, skilled craftsmanship, and rigorous process control to ensure each part meets the highest standards of strength, accuracy, and finish. Even for unique or one-off parts, we maintain our highest standards, giving you the confidence that every component performs as designed.

Our low-volume and one-off production services are ideal for industries where innovation, performance, and customization are critical, including aerospace, motorsport, marine, and sporting goods. With our precise, scalable approach, we deliver lightweight, durable, and visually flawless carbon fiber components—even for single-piece production—helping our clients bring innovative designs from concept to reality with speed, quality, and confidence.