Our Facilities

-

20.000 Sq Ft Facility

We have a large facility with plenty of storage to scale to your needs. Spread out over 2 floors, we have dedicated zones for each step of the manufacturing process.

-

Temperature Controlled Clean Room

Our Clean Room is where we build the most critical components and also where we cut our kits. This space is temperature controlled to keep the carbon fiber at its most stable temperature before curing.

-

CNC Kit Cutter

We have a large Gerber Paragon Cutter with its own space within the Clean Room. We add our rolls of Carbon Fiber and out comes kits, cut and labeled for our composite technicians to make into your products

-

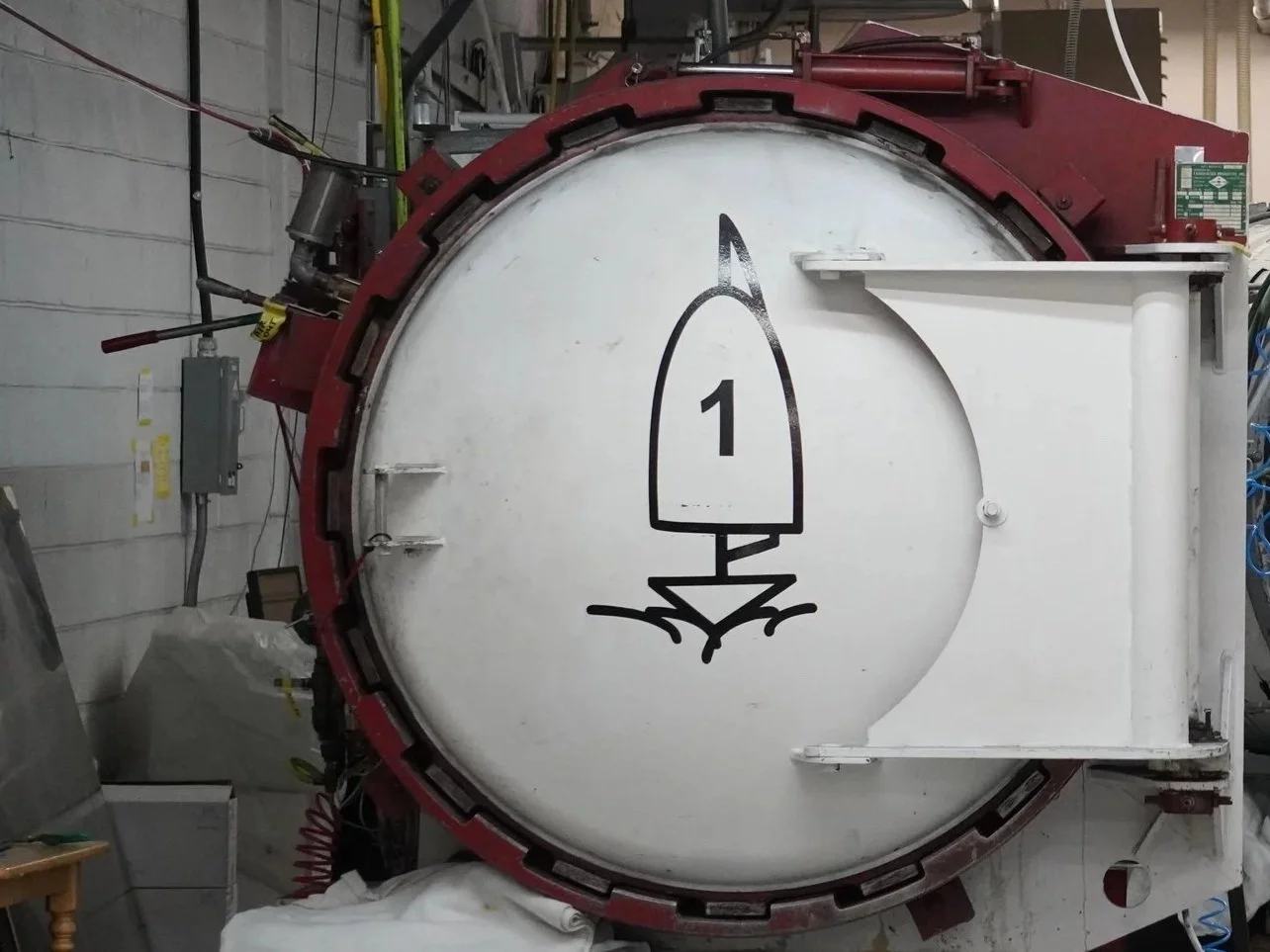

2 Autoclaves

We have 2 large Autoclaves for curing the parts into their final shapes. With a combination of heat and pressure, the parts come out void free and of optimal strength. These Autoclaves have an internal measurement of: 6ft X 15ft

-

3-Axis Gantry CNC

Our large Ganry style CNC is 8ft x 4ft x 4in and this is what we use to cut our simple molds and or cut parts to final size. We have a fantastic partner for products that need 5 Axis cutting. They can fit a whole car into their CNC. No part is to big for them!

-

Dedicated Trimming Room

This is where we remove the excess flash and carbon and cut the parts to their final dimensions. Using a combination of hand and fixed tooling